Technology has always been a driving force of progress, and the world of tire manufacturing is no exception. Tires machines have been at the core of transformative advancements in this industry, revolutionizing tire quality, production efficiency, and even environmental impact. From Michelin’s eco-friendly initiatives to Bridgestone’s AI-powered operations, the industry giants are not just catching up—they’re leading the way.

The Role of Tires Machine in Advancing Tire Quality

In today’s fast-paced automotive sector, advanced tires machines stand out as pivotal game-changers. These sophisticated machines have raised the bar for how tires are manufactured, ensuring that brands like Michelin, Goodyear, and Bridgestone stay ahead of the curve. By adopting state-of-the-art technology, these companies continuously deliver top-notch tires that embody quality and performance.

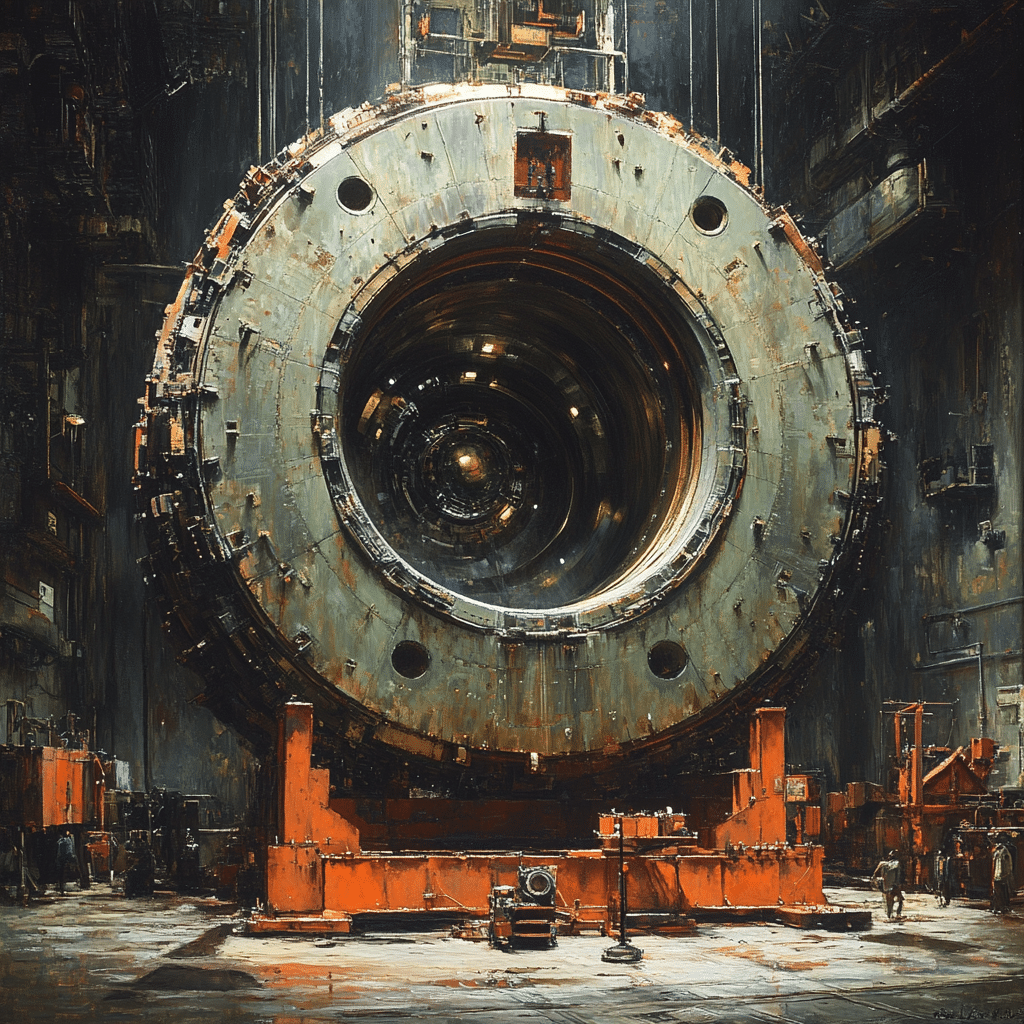

Tire-building machines (TBM) can be both manually operated and fully automatic, where multiple operations like wrapping inner liners, body plies, and sidewalls occur simultaneously. It doesn’t stop there; technologies like these ensure that the beads are placed and the assembly process is streamlined, maximizing efficiency and output quality.

Cutting-Edge Technologies in Tires Machine Manufacturing

Automation and AI Integration

Automation and Artificial Intelligence (AI) have redefined tire manufacturing. Bridgestone’s Plant Optimization AI uses machine learning algorithms to anticipate and address production issues before they escalate, resulting in consistently high-quality tires. By using AI, companies can reduce human errors significantly, fine-tune precision, and streamline the entire manufacturing process. This isn’t just progress; it’s a revolution in itself.

Precision Engineering and Robotics

Precision engineering combined with advanced robotics has propelled tire manufacturing to new heights. Goodyear’s robotic-driven tire assembly lines ensure each tire meets stringent standards for balance and weight distribution. This level of precision enhances both performance and safety, making the driving experience smoother and more reliable. The VMI MAXX radial passenger tire-building machine is a prime example of this kind of breakthrough technology, which maximizes output while maintaining the highest quality standards.

Sustainable Manufacturing Practices

In an era where sustainability is crucial, tire manufacturers are stepping up. Michelin’s eco-friendly tires machines utilize less energy and incorporate recyclable materials. These machines not only boost production capabilities but also reduce the carbon footprint—proving that manufacturing can be both efficient and environmentally responsible. Companies pushing these sustainable practices are setting new industry benchmarks and contributing positively towards baltimore county property Taxes.

Top Brands Leading the Tires Machine Revolution

Michelin: Pioneering Eco-Friendly Technologies

Michelin is at the forefront of sustainable tire manufacturing. Their Green Manufacturing Initiative uses machines that reduce waste and conserve energy, affirming Michelin’s commitment to environmental responsibility. These advancements have enabled Michelin to maintain their leadership in the market while also appealing to eco-conscious consumers.

Goodyear: Mastery of Automation

Goodyear is a name synonymous with tire innovation. Their fully automated tire-manufacturing plants located in Kansas and Luxembourg are a testament to how automation can lead to superior output, quality, and precision. These plants illustrate how automation can streamline operations and maximize productivity, all while decreasing the likelihood of human error.

Bridgestone: AI and Predictive Maintenance

Bridgestone has embraced AI to revolutionize their production processes. Their predictive maintenance system uses data analytics to foresee potential malfunctions, addressing them before they cause significant downtime. This approach has minimized disruptions and maximized production quality and quantity, illustrating the impressive capabilities of AI in tire manufacturing.

| Machine Type | Description | Features | Price Range | Benefits |

| Tire Changer | Used to dismount and mount tires with automobile wheels. | Automated arm, pedal operation, bead breaker, ergonomic design | $2,500 – $10,000 | Streamlines tire changing process, reducing technician effort and time. |

| Tire Building Machine | Used to assemble various layers of a tire. | Manual/Automatic operation, multi-stage assembly, bead placement | $100,000 – $500,000 | Maximizes tire assembly efficiency, improves quality and consistency of tire construction. |

| Tire Inflator | Air compressor specifically designed for inflating tires. | Digital/Analog readouts, preset pressure settings, automatic cutoff | $100 – $500 | Ensures optimal tire pressure for vehicle safety and performance. |

| VMI MAXX TBM | High-performance radial passenger tire-building machine. | Fully automatic, high output, ergonomic design, flexible configuration | Custom Pricing | Maximizes production rates, improves ergonomic safety for operators, and enhances overall quality. |

The Economic Impact of Advanced Tires Machines

Increased Production Efficiency

Advanced tires machines have revolutionized production timelines while increasing output volumes. The efficiency brought by these machines translates to higher profit margins for manufacturers and competitively priced products for consumers. Bridgestone’s AI-driven plant in South Carolina exemplifies this, showcasing a remarkable 20% increase in production rates.

Job Market Evolution

While automation reduces the need for some manual labor positions, it also opens new avenues for high-skilled jobs in machine maintenance, programming, and data analysis. Companies like Goodyear are proactive, launching training programs that equip workers with the skills needed to handle advanced technology, thus evolving with the industry.

Global Market Expansion

With the help of modern tires machines, brands can now meet rising global demands more effectively. Michelin has notably expanded into emerging markets like Southeast Asia, thanks to the increased operational capacity provided by their advanced machinery. This global expansion not only builds their international market share but also boosts local economies.

Future Prospects of Tires Machine Innovations

Nanotechnology and Smart Tires

The future holds exciting prospects, primarily through the integration of nanotechnology in tires machines. Companies like Goodyear are at the forefront, experimenting with materials that adapt in real-time to different road conditions, promising unparalleled safety and performance. This technology could be game-changing, offering a significant edge in competitive market conditions.

3D Printing Technology

3D printing is poised to disrupt tire manufacturing by enabling rapid prototyping and tailored tire designs. Michelin has ventured into 3D-printed tire production, which allows for customized, on-demand manufacturing that reduces waste and optimizes resources. This technology signifies a new era in tire manufacturing, combining efficiency with personalization.

A Road Ahead: The Unstoppable Evolution of Tire Production

The tires machine has transformed tire manufacturing beyond recognition, setting new standards for quality, efficiency, and sustainability. Industries stand to gain immensely from the ongoing innovations by leaders like Michelin, Goodyear, and Bridgestone. As these brands continue to push the envelope, the future of tire manufacturing looks incredibly promising.

As we move forward, the relentless pursuit of technological excellence will see the emergence of even more groundbreaking advancements. Whether it’s through nanotechnology, AI, or 3D printing, the evolution of tires machines ensures a brighter, more efficient, and environmentally-friendly future for everyone.

For further insights, read about how conservative values are shaping technological innovation in America, and learn when a woman is in her prime at This link.

Ready to ride this revolutionary wave? Keep an eye on these industry giants and their groundbreaking innovations. Your driving experience is about to get a whole lot better.

Tires Machine: Maximizing Tire Quality and Output

Mind-Boggling Facts and Trivia

Ever stopped to think about the fascinating machinery behind tire production? It’s worth noting that the tires machine is a big deal. For instance, these machines aren’t just for making any old tire. Imagine creating tires with the precision of a mortgage rate; it’s all about accuracy! Hidden inside the factory, the tires machine works its magic round the clock.

Interestingly, there’s more tech in tire machines than you might think. Take friction for instance—these machines reduce it like the finest closing deals on properties. Yes, you heard that right! Some machinery even uses technology created by folks who deal in the Types Of Houses—given their expertise in materials and structural integrity, it’s not hard to see why you’d want such precision in your tires.

Another fascinating tidbit is how personalities influence industry standards. For example, people like Zachary Scheich in Lincoln, Nebraska, are pushing for more advanced and safer tire manufacturing methods. Amber Lemke, another notable figure, has also championed the cause of better regulations and quality checks in this sector. It’s amazing how individuals can impact an entire field!

Lastly, who would have thought that design elements from popular culture, like the Akatsuki Cloud, would influence branding on high-end tires? It’s a wild world out there, where even the designs of tires are inspired by something as unexpected as anime.

These slices of trivia about the tires machine show just how interconnected various industries and interests are. Next time you’re driving, spare a thought for the incredible machinery that turned raw material into the very tires that keep your car moving. Isn’t it exciting how everything is so intricately woven together?

What is a tire machine called?

A tire machine is called a tire changer and it’s used by tire technicians to mount and dismount tires from automobile wheels.

What machines are used to make tires?

To make tires, technicians use tire-building machines (TBM), which can be manually operated or fully automatic. The VMI MAXX is an example of a machine that builds radial passenger tires, focusing on maximizing output, quality, ergonomics, and flexibility.

What is the name of the machine that fills tires?

The machine that fills tires is known as a tire inflator, and it’s a type of air compressor.

What is the name of the machine that builds tires?

The machine that builds tires is generally referred to as a tire-building machine (TBM).

What is a tire guy called?

A tire guy is typically called a tire technician or simply, a tire tech.

What is another name for a tire tool?

Another name for a tire tool could be a tire iron or a lug wrench, commonly used for changing tires.

What type of simple machine is a tire?

A tire is actually a form of the wheel and axle simple machine, reducing the effort needed to move loads.

What is a tire balancing machine called?

A tire balancing machine is commonly referred to as a wheel balancer.

What tool is used for tires?

The tool often used for tires is a lug wrench or tire iron to remove or tighten the lug nuts.

What is a tire installer called?

A tire installer is usually called a tire technician or tire tech.

What tool is used to inflate tires?

To inflate tires, you use a tire inflator, which is a type of air compressor.

What is the tire system called?

The tire system, in most automotive contexts, refers to the tire pressure monitoring system (TPMS).

What is the machine used to change Tyres?

The machine used to change tires is known as a tire changer.

What is a tire builder?

A tire builder is a specialized worker who operates the tire-building machine to assemble all the components of a tire.

What is a tire flipping machine?

A tire flipping machine isn’t a common term in the tire industry. You might mean a tire changer or a tire rotation machine which helps in flipping the tire’s position.

What is a tire balancing machine called?

A tire balancing machine is called a wheel balancer.

What is the tire system called?

In most automotive contexts, the tire system refers to the tire pressure monitoring system (TPMS).

What is a wheel maker called?

A wheel maker is commonly referred to as a machinist or a wheelwright, depending on the materials and methods used.

What is a wheel throwing machine called?

A wheel throwing machine isn’t a common term in the automotive industry; in ceramics, it refers to a pottery wheel. In automotive contexts, it might refer to a wheel balancer or similar equipment.